Sunday was a grueling day- but an extremely productive one. Mama and I rented a miter saw from Home Depot (I swear I'm not sponsored by them- there just happens to be one down the street and so far Rona hasn't given me the products or the service I need to make the extra 10 minute drive. A Lowes is opening up 2 minutes away from the house in October- so we'll see then if my preferences change.)

We cut baseboards. All. Day.

The baseboards themselves we bought earlier in the week while they were on sale- 45 cents a linear foot down from 75 cents! Booyah! They were exactly what we wanted and since we had a LARGE set of interconnected areas to do- we struck while the iron was hot. We'll buy the same ones for the rest of the house as we do those rooms.

The saw rental was supposed to be 36$ for the day, but there was a mixup and we ended up getting it for 24$ for 24 hours- worth every penny! We actually started cutting around 1pm on Sunday, and finished at 9pm- eight hours of cutting. It felt like forever.

I can't take much credit- I have the math skills of a gnat, and that makes doing anything more complicated than 45 or 22.5 degree cuts extremely challenging. My talented Mama figured out all the annoying cuts for the stairs- it was like a very annoying jigsaw puzzle. Don't ask me how she did it cause I have no idea. All I know is that if I ever need the baseboards replaced on stairs again- we're hiring a pro. Not that my Mom didn't do a good job- she did an amazing job! It was just so time consuming and exhausting.

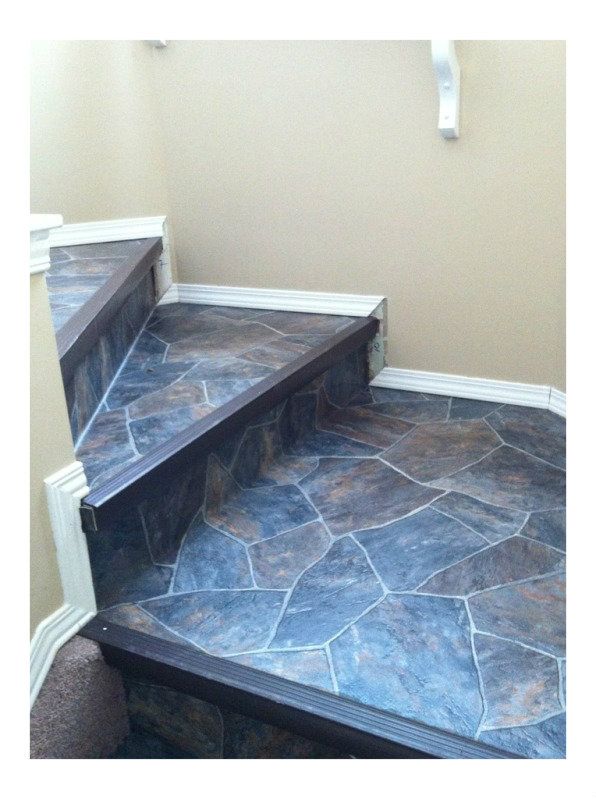

So we got all the cuts done in our 24 hours! Yay!! For a reminder- this is what we started with:

The only thing that remains of that photo is the stair railing. The paint colour is gone, the ugly lino is gone (I bet you can't wait to see what's there to replace it!) and the horrible unfinished window casing being used as baseboard is gone. ALL GONE!

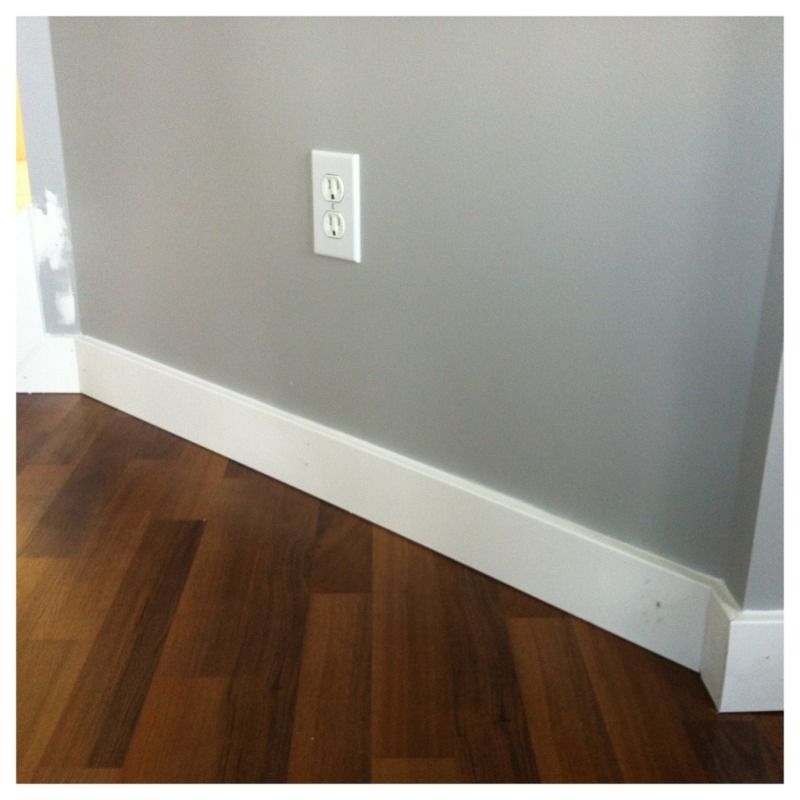

But I'm not going to show you the stairs yet because they're not QUITE finished and I want to do a big reveal when they are. So instead I show you the wall where I will eventually instal an electric fireplace:

Ignore the white patch on the left- we had to cover up a boo boo there. It'll get paint when we do touch ups.

Aren't they gorgeous!? Now THAT is baseboard! Today we pre-painted the pieces using our Semi-Gloss Kilz Pro-X paint, then pre-drilled most of the way through and installed into the studs with 1.5 inch finishing nails. Then we patched the holes with drywall compound and caulked the edges with AlexPlus paintable caulking in bright white. They still need to be painted to cover the nails- but they're IN! I can't believe it- on Sunday I never thought we'd get them done- and now they're installed!!

I'm beside myself I'm so happy. There were three big things we hated about this house (obviously not enough to not buy it- but still rather large things): the back yard, the baseboards, and the stairs. By the end of this week one of those will be completely off the list- and the other- the baseboards- will be well on it's way out as well! Hubsbeast is working slowly on the back yard- it's his project, not mine.

AH! So happy that the craptastic trim is gone!! Next time I post it'll be about staining and polying the stairs.

So what do you think? Improvement?

7.31.2012

7.29.2012

Painting Tips according to my Mama

So, as I said in my last post- my Mom painted for me. This past week I had to work in the afternoons, and while I helped a tad in the morning before I had to go pick up my client- Mom continued after I left. She painted the whole front entrance/ livingroom/ stairwell/ upstairs hallway all by herself- TWICE. I can't thank her enough- the colour the previous owners had on the walls was giving me hives I swear. You've seen it in the pictures of the stairs pre-reno- a peachy beige that set my teeth on edge- probably because it clashed so horribly with the dark walnut floors downstairs and the oak stairs upstairs.

I did manage to get some awesome painting tips from my Mama before rushing off to work though- so I'll share those with you here, cause my Mom is the painting wizard extraordinare and extremely picky about her paint jobs- if my Mom tells you how to do something- you can take it to bank.

1) Don't bother taping off your trim while doing the wall colour. Just get a really good 1 inch thin-edged paintbrush (she likes the Purdy brushes sold at Home Depot) and cut in. Cutting in is a lot easier than I expected- just don't put to much paint on your brush, and slowly follow the edge of your trim. Keep a damp rag with you (I bought a big box of rags before we started the renos and they are getting used!) and wipe it off if you get a lot on the trim. Once your wall colour has two coats and is dry- THEN tape off the trim and paint it. We've been using FrogTape (just the 1 inch multi-surface one) and it's been working really well.

2) Use eggshell or satin finish on your walls. Flat paint scruffs like crazy- and it'll stop looking new almost instantly. I'm using eggshell on my walls because I like the look of flat but not how easy it is to mess up- that tiny bit of sheen makes it all that much more forgiving.

3) Use untinted Kilz Pro-X for your trim. It blocks stains, and if you don't get it tinted you'll have crisp beautiful white no matter what. Get it in semi-gloss to make it easy to clean. And even though you aren't having it tinted, have it shaken at the paint counter.

4) Remove all the light switch/ outlet covers first! This seems obvious but I was about to cut in around one when she stopped me. TAKE EM OFF!

5) Invest in good equipment. Chances are you aren't just going to ever paint one room in your life. Get a good roller cage (the pro ones at Home Depot with black and yellow handles work awesome), get good rollers (again, she likes Purdy White Dove) and brushes. It really does affect the finish of your walls. And you'll use them over and over and over.

6) Get a contractor pack of rollers- once you clean them they never have quite the same finish to them again- and they're pretty cheap. Use one, and toss.

7) Against popcorn ceilings- don't even attempt to tape. You'll make a huge mess. Just get out that thin edged brush you bought and cut in- kind of in a stippling motion. You'll be surprised by how easy it is. Then pull the paint out a good two to three inches from the ceiling so you don't have to go anywhere near the popcorn with your roller- which is the kiss of death.

For this room I chose Behr's paint and primer in one- and it worked incredibly well. After two coats the walls looked flawless. It's also a lot cheaper than Benjamin Moore or Dulux. We used just under two gallons for the entire front entrance/ livingroom/ double height stairwell/ upstairs hallway area- it went really far!! And we only needed one gallon of the Kilz Pro-X for the trim.

I don't have any other pictures of the room yet because it's still a disaster zone- today we cut new baseboards!! But I'll write about that next time. This entire area is really coming together- I can't believe it's the same house! I can't thank my Mom enough for painting for me- now when I wake up in the morning I don't immediately feel all upset- my new colour is so much more calming! Thank you Mommy!!

|

| Old colour on the right- peachy gross. New colour on the left in the entrance- Classic Silver by Behr. |

1) Don't bother taping off your trim while doing the wall colour. Just get a really good 1 inch thin-edged paintbrush (she likes the Purdy brushes sold at Home Depot) and cut in. Cutting in is a lot easier than I expected- just don't put to much paint on your brush, and slowly follow the edge of your trim. Keep a damp rag with you (I bought a big box of rags before we started the renos and they are getting used!) and wipe it off if you get a lot on the trim. Once your wall colour has two coats and is dry- THEN tape off the trim and paint it. We've been using FrogTape (just the 1 inch multi-surface one) and it's been working really well.

2) Use eggshell or satin finish on your walls. Flat paint scruffs like crazy- and it'll stop looking new almost instantly. I'm using eggshell on my walls because I like the look of flat but not how easy it is to mess up- that tiny bit of sheen makes it all that much more forgiving.

3) Use untinted Kilz Pro-X for your trim. It blocks stains, and if you don't get it tinted you'll have crisp beautiful white no matter what. Get it in semi-gloss to make it easy to clean. And even though you aren't having it tinted, have it shaken at the paint counter.

4) Remove all the light switch/ outlet covers first! This seems obvious but I was about to cut in around one when she stopped me. TAKE EM OFF!

5) Invest in good equipment. Chances are you aren't just going to ever paint one room in your life. Get a good roller cage (the pro ones at Home Depot with black and yellow handles work awesome), get good rollers (again, she likes Purdy White Dove) and brushes. It really does affect the finish of your walls. And you'll use them over and over and over.

6) Get a contractor pack of rollers- once you clean them they never have quite the same finish to them again- and they're pretty cheap. Use one, and toss.

7) Against popcorn ceilings- don't even attempt to tape. You'll make a huge mess. Just get out that thin edged brush you bought and cut in- kind of in a stippling motion. You'll be surprised by how easy it is. Then pull the paint out a good two to three inches from the ceiling so you don't have to go anywhere near the popcorn with your roller- which is the kiss of death.

For this room I chose Behr's paint and primer in one- and it worked incredibly well. After two coats the walls looked flawless. It's also a lot cheaper than Benjamin Moore or Dulux. We used just under two gallons for the entire front entrance/ livingroom/ double height stairwell/ upstairs hallway area- it went really far!! And we only needed one gallon of the Kilz Pro-X for the trim.

I don't have any other pictures of the room yet because it's still a disaster zone- today we cut new baseboards!! But I'll write about that next time. This entire area is really coming together- I can't believe it's the same house! I can't thank my Mom enough for painting for me- now when I wake up in the morning I don't immediately feel all upset- my new colour is so much more calming! Thank you Mommy!!

7.26.2012

Updating the Stairs- Continued.

We papered the stairs!! Unfortunately I don't have a ton of photos of the process for you, as cameras plus glue filled hands don't really go together. But I do have befores and afters. So if you remember- the last time I posted we'd gotten as far as nailing and glueing trim along the front of the existing treads to give us a smooth, finished nosing. That was a lot of work- but I'm going to tell you now- if your nosings look anything like mine did- DO NOT skip that step! It's so important for the finished look. There were some gaps between the old edge and the new trim (a few were really gauged) but we didn't bother filling that in with wood filler.

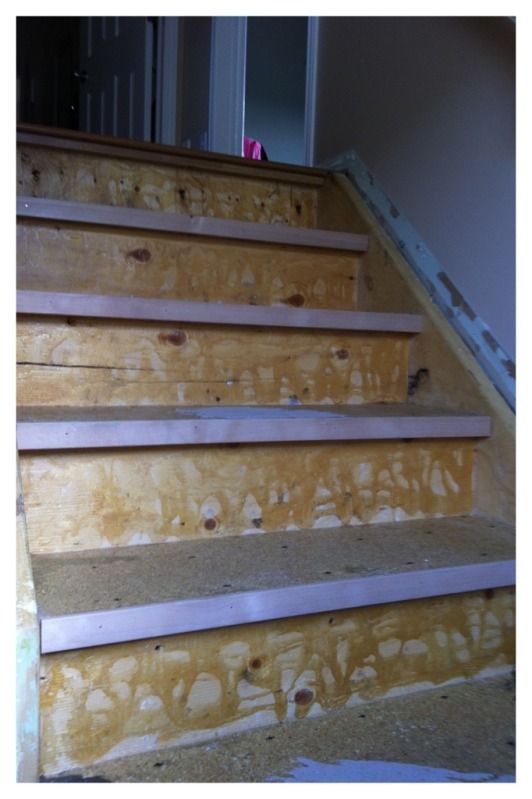

The next step was to actually get down to papering!! We started with the stairs looking like this:

No lino, new trim on the edges. The perfect canvas. Had there been holes in the treads (like if we'd pulled up carpet) we'd have filled those in with wood filler and sanded- but the lino left us with a pretty pristine surface.

Here's where we don't have any pictures. The basic method I followed was one I found via Pinterest on Lovely Crafty Home- the Ultimate Brown Paper Flooring Guide. This was the post that really got me thinking about doing paper floors on the stairs, and with her step by step commentary- I really felt like it was something I could handle.

Rachael suggested a 3 to 1 mix of water and white glue- so that's exactly what we used. She used brown craft paper, and we're using dry sheathing (both cheaper than any brown craft paper I could find, and I like the more woody look of it- it's a much more fibrous paper) but it worked just as well. I wouldn't mess with that. We did 6 cups of water and 2 cups of glue at a time.

There really isn't any technique to this- but there is a method. First- my Mom and I found it much easier to tear up the sheathing into bits before we started. Once you're in the thick of it your hands are full of glue and tearing paper would just make a huge mess. It also comes on a massive roll and there was no way I was going to get that up and down the stairs easily. So we spent one evening tearing and crumpling and tossing it into a recycling bag.

Second- When doing stairs, do every second tread- then let it dry. The dry sheathing falls apart a bit when it's wet, and we had just enough time to dunk it, squeeze it, put it place and smooth it down before it disintegrated. If we'd tried to walk on it while wet we'd have destroyed it. So in the interest of being able to sleep in our own beds, we did every second tread, and then the next day once the first set were dry we did the others. Once dry you can walk on them until you're ready to stain and poly.

And that's about it. Use your cheap paintbrush from the dollar store to paint on some glue mixture to the tread first. Then you take a piece out of your pre-torn bag, check to see if it has a straight edge (best for along the stringers, and along the riser edge) and then dunk it into the glue/water mix in the bucket, squeeze it out, and place it on the stair tread.

Repeat, overlapping the edges a bit and smoothing them together (the fibrous nature of the sheathing really allowed the pieces to be smoothed well) as you go. The paintbrush is also useful for this. Wrap pieces around from the top of the tread to the underside of the nosing- smoothing well. Don't worry about what the underside of the nosing looks like- you don't need straight pieces and you don't need to cover it all the way to the riser below. Nobody looks at the underside of your stair nosings. Trust me.

Continue this process, starting with the top tread and working your way down the stairwell. We tried it both ways- up and down, and the down worked a lot better. It's really hard to do the nosing from above.

So after that we were left with this:

Once again, notice the hopping spots on the treads we'd skipped. Doesn't that look so much better?! Since we had no finished nose to our stairs, and we put the straight squared trim on to finish it- we really got a very modern, clean looking tread out of it. And the next day when we'd done the last half:

Doesn't that look incredible!? I can't believe how well it turned out. That's DRY SHEATHING on my stairs!

One more look?

It's crazy how much better they look already!! And yes- you're very perceptive- you've noticed that the colour on the walls has changed somewhere between those two photos. We decided after the paper was dry that we should paint the stairwell and living room before we started in on staining and polying because as Rachael of Lovely Crafty Home says- the stain never fully dries, and the poly takes a while to cure. We have a big double height stairwell and didn't want to put the pressure of the ladder on freshly poly'd stairs for fear of ruining it- so we decided to paint first, and if we got some paint on them or tore a bit up with the ladder that we could just rip off some more sheathing (because honestly- I still have enough on that roll to do another full staircase and probably one for my neighbours on either side too.) In the end the ladder really didn't damage them at all, and there are only a few spots where the drop cloth didn't catch the drips that we need to go over. But I'll post about the paint change in depth later.

So before we stain and poly we still need to put down the new base boards (as I'm sure you noticed in the before pictures- the previous owners couldn't cut a base board to save their lives- and it wasn't baseboard- it was window casing!) Then once we've got that under control we can go ahead and stain and poly. And I'll post about that when it happens too. The last step will be to cover the risers. We've figured out an easy and relatively cheap way to fix those, so I'll be sure to post about that process as well!

So my next posts will be about painting (and the lessons I learned from my Mom- the paint wizard extraordinaire) and baseboard installation. But the finished stairs aren't far away- hopefully!

The next step was to actually get down to papering!! We started with the stairs looking like this:

No lino, new trim on the edges. The perfect canvas. Had there been holes in the treads (like if we'd pulled up carpet) we'd have filled those in with wood filler and sanded- but the lino left us with a pretty pristine surface.

Here's where we don't have any pictures. The basic method I followed was one I found via Pinterest on Lovely Crafty Home- the Ultimate Brown Paper Flooring Guide. This was the post that really got me thinking about doing paper floors on the stairs, and with her step by step commentary- I really felt like it was something I could handle.

Rachael suggested a 3 to 1 mix of water and white glue- so that's exactly what we used. She used brown craft paper, and we're using dry sheathing (both cheaper than any brown craft paper I could find, and I like the more woody look of it- it's a much more fibrous paper) but it worked just as well. I wouldn't mess with that. We did 6 cups of water and 2 cups of glue at a time.

There really isn't any technique to this- but there is a method. First- my Mom and I found it much easier to tear up the sheathing into bits before we started. Once you're in the thick of it your hands are full of glue and tearing paper would just make a huge mess. It also comes on a massive roll and there was no way I was going to get that up and down the stairs easily. So we spent one evening tearing and crumpling and tossing it into a recycling bag.

Second- When doing stairs, do every second tread- then let it dry. The dry sheathing falls apart a bit when it's wet, and we had just enough time to dunk it, squeeze it, put it place and smooth it down before it disintegrated. If we'd tried to walk on it while wet we'd have destroyed it. So in the interest of being able to sleep in our own beds, we did every second tread, and then the next day once the first set were dry we did the others. Once dry you can walk on them until you're ready to stain and poly.

And that's about it. Use your cheap paintbrush from the dollar store to paint on some glue mixture to the tread first. Then you take a piece out of your pre-torn bag, check to see if it has a straight edge (best for along the stringers, and along the riser edge) and then dunk it into the glue/water mix in the bucket, squeeze it out, and place it on the stair tread.

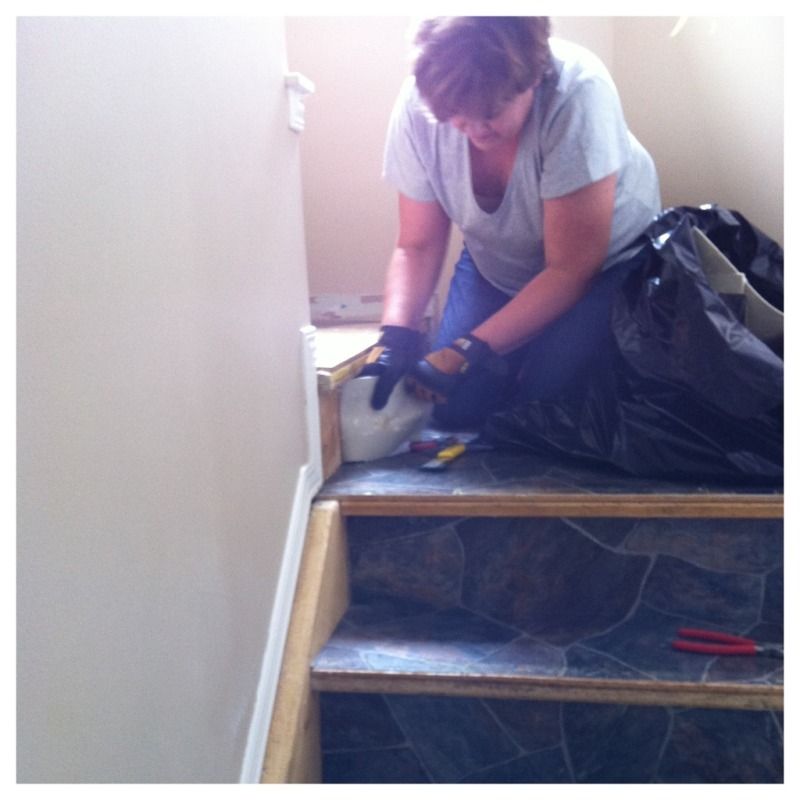

|

| Me, up to my elbows in white glue mix, papering the stairs. |

Repeat, overlapping the edges a bit and smoothing them together (the fibrous nature of the sheathing really allowed the pieces to be smoothed well) as you go. The paintbrush is also useful for this. Wrap pieces around from the top of the tread to the underside of the nosing- smoothing well. Don't worry about what the underside of the nosing looks like- you don't need straight pieces and you don't need to cover it all the way to the riser below. Nobody looks at the underside of your stair nosings. Trust me.

Continue this process, starting with the top tread and working your way down the stairwell. We tried it both ways- up and down, and the down worked a lot better. It's really hard to do the nosing from above.

So after that we were left with this:

Once again, notice the hopping spots on the treads we'd skipped. Doesn't that look so much better?! Since we had no finished nose to our stairs, and we put the straight squared trim on to finish it- we really got a very modern, clean looking tread out of it. And the next day when we'd done the last half:

Doesn't that look incredible!? I can't believe how well it turned out. That's DRY SHEATHING on my stairs!

One more look?

It's crazy how much better they look already!! And yes- you're very perceptive- you've noticed that the colour on the walls has changed somewhere between those two photos. We decided after the paper was dry that we should paint the stairwell and living room before we started in on staining and polying because as Rachael of Lovely Crafty Home says- the stain never fully dries, and the poly takes a while to cure. We have a big double height stairwell and didn't want to put the pressure of the ladder on freshly poly'd stairs for fear of ruining it- so we decided to paint first, and if we got some paint on them or tore a bit up with the ladder that we could just rip off some more sheathing (because honestly- I still have enough on that roll to do another full staircase and probably one for my neighbours on either side too.) In the end the ladder really didn't damage them at all, and there are only a few spots where the drop cloth didn't catch the drips that we need to go over. But I'll post about the paint change in depth later.

So before we stain and poly we still need to put down the new base boards (as I'm sure you noticed in the before pictures- the previous owners couldn't cut a base board to save their lives- and it wasn't baseboard- it was window casing!) Then once we've got that under control we can go ahead and stain and poly. And I'll post about that when it happens too. The last step will be to cover the risers. We've figured out an easy and relatively cheap way to fix those, so I'll be sure to post about that process as well!

So my next posts will be about painting (and the lessons I learned from my Mom- the paint wizard extraordinaire) and baseboard installation. But the finished stairs aren't far away- hopefully!

7.22.2012

Stair Redo Day 2

So, continuing on my story about the stairs.

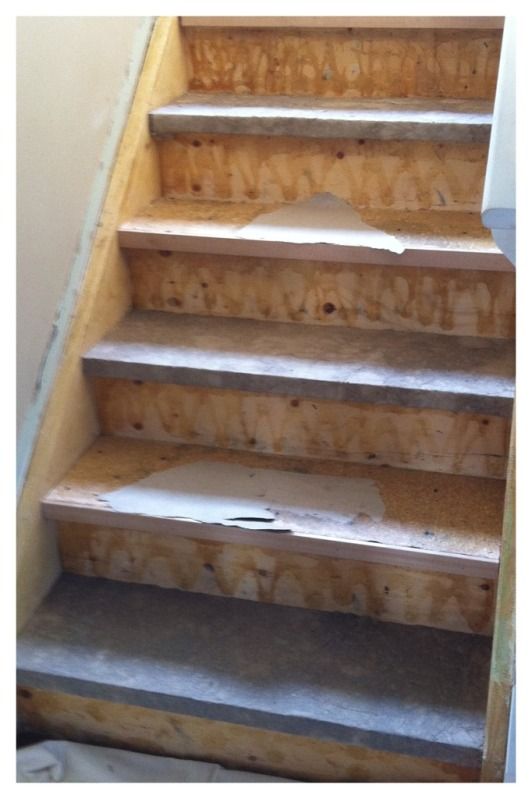

Sunday- Day 2- we got to start the real fun. ACTUALLY transforming the stairs. We still had some prep work to do though. First, we ripped up any of the lino that was left, and just put down some extra sheathing so we could get up and down. The lino left a lot of really tacky glue on the treads- so going up them was like being stuck to human fly paper. Not fun. You'll notice our "hopping spots" in several photos.

The issue with our stairs was that they weren't meant to not be carpeted. They were cheap, builder grade, structural stairs. If you know anything about the speed with which houses were built in Edmonton during the last boom, you'll understand- these houses were built to house bodies. They are the furthest thing from custom known to man. My aim is to change this builder grade house into something really special. But more on that later.

So- structural stairs. Made of plywood and particle board. The treads were smooth and level because whomever installed the lino put new fiber board on top of the existing particle board treads in order to level them. But the edges were...well...take a look:

Can't see? Look at the worst of the bunch:

That's the first of the winding treads. See how uneven and generally gross they are? My original idea was to fill them with wood filler and sand them smooth. But since they were in SUCH bad shape, my Mom came up with a better idea while we were in Home Depot: trim. So we measured the width of the tread and discovered they were all approximately 1.5 inches wide. Some were a hair under, but that was okay. When was the last time you laid down and looked UNDER the nosing of your stairs? Yeah, thought so.

So we measured how long each tread was and bought 41 feet of Hemlock door and window casing that was 1.5 inches wide. It was perfect- straight, smooth, and the right width. Sunday we measured each tread again and cut a piece of moulding to fit. Each piece was then pre-nailed with finishing nails, and we applied PL400 construction adhesive on the back. Then we fit them in place, and finished nailing the nails through. It was SUCH an improvement already!! Look!

Doesn't that look worlds better already!? It made the stairs look smooth and clean- perfect. And that one I showed you earlier with the torn up corner?

Mitered, and the sunken part where the new fiber board wasn't cut to fit filled in with a scrap. So. Much. Better.

That's a view of all the winding treads meeting in the middle.

So now all the stairs are properly nosed. They don't look like a dog chewed on them anymore. Which is important, if we're going to go to all this trouble of papering them and staining them and polying them, they'd sure as heck better look smooth and professional when they're done. A few hours of prep, but so worth the 60$ in trim and the time. Taking a page out of Mike Holmes' book: Do It RIGHT the first time!

Next post will be about the actual papering process. With the nosings done, and the mess all cleaned up (yeah- try and keep your work area clean, it really helps!) we were ready to paper!!

Sunday- Day 2- we got to start the real fun. ACTUALLY transforming the stairs. We still had some prep work to do though. First, we ripped up any of the lino that was left, and just put down some extra sheathing so we could get up and down. The lino left a lot of really tacky glue on the treads- so going up them was like being stuck to human fly paper. Not fun. You'll notice our "hopping spots" in several photos.

The issue with our stairs was that they weren't meant to not be carpeted. They were cheap, builder grade, structural stairs. If you know anything about the speed with which houses were built in Edmonton during the last boom, you'll understand- these houses were built to house bodies. They are the furthest thing from custom known to man. My aim is to change this builder grade house into something really special. But more on that later.

So- structural stairs. Made of plywood and particle board. The treads were smooth and level because whomever installed the lino put new fiber board on top of the existing particle board treads in order to level them. But the edges were...well...take a look:

Can't see? Look at the worst of the bunch:

That's the first of the winding treads. See how uneven and generally gross they are? My original idea was to fill them with wood filler and sand them smooth. But since they were in SUCH bad shape, my Mom came up with a better idea while we were in Home Depot: trim. So we measured the width of the tread and discovered they were all approximately 1.5 inches wide. Some were a hair under, but that was okay. When was the last time you laid down and looked UNDER the nosing of your stairs? Yeah, thought so.

So we measured how long each tread was and bought 41 feet of Hemlock door and window casing that was 1.5 inches wide. It was perfect- straight, smooth, and the right width. Sunday we measured each tread again and cut a piece of moulding to fit. Each piece was then pre-nailed with finishing nails, and we applied PL400 construction adhesive on the back. Then we fit them in place, and finished nailing the nails through. It was SUCH an improvement already!! Look!

|

| Pre-nailed every few inches. Nothing precise. If it looked like we needed more, we added more. |

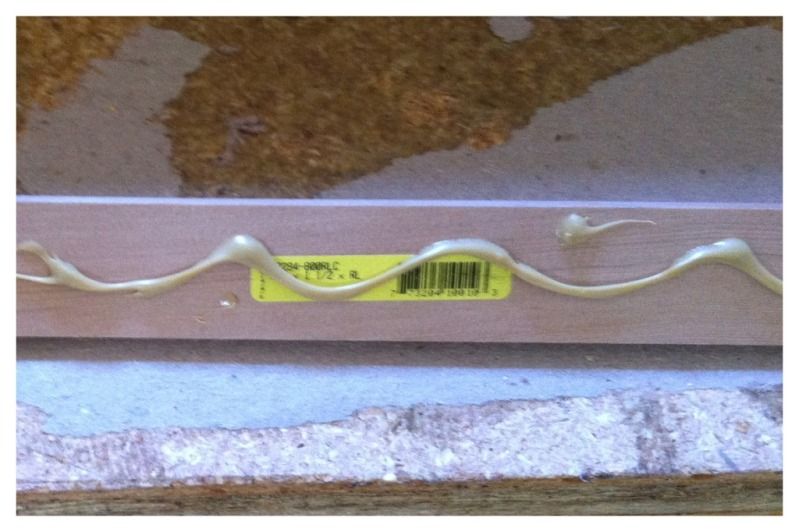

|

| Glue in a wave pattern. A la Mike Holmes. |

|

| TA DA!! Bottom stair with new nosing, top stair with ugly old nosing. |

Mitered, and the sunken part where the new fiber board wasn't cut to fit filled in with a scrap. So. Much. Better.

That's a view of all the winding treads meeting in the middle.

So now all the stairs are properly nosed. They don't look like a dog chewed on them anymore. Which is important, if we're going to go to all this trouble of papering them and staining them and polying them, they'd sure as heck better look smooth and professional when they're done. A few hours of prep, but so worth the 60$ in trim and the time. Taking a page out of Mike Holmes' book: Do It RIGHT the first time!

Next post will be about the actual papering process. With the nosings done, and the mess all cleaned up (yeah- try and keep your work area clean, it really helps!) we were ready to paper!!

And so it begins...

So we've started the stairs!! When Mom got here on Thursday she agreed we needed to start first thing Friday- so we did. Well- we tried. We got sidetracked and went for a manicure first. For the record- Shellac manicures last through DIY work extremely well.

SATURDAY we got going. We head to Home Depot with a list and a mission: get all the supplies for the stairs, and to paint the main area of the house. We succeeded.

But this post is about the stairs.

We went all over Home Depot gathering our loot. And this is what we ended up with. All the supplies (not including tools) cost approximately 195$.

Dry Sheathing for the actual treatment (found in the roofing aisle.)

A big gallon bucket

A caulking gun

PL400 glue in a caulk tube

MinWax Oil-Modified Water Based Poly

Smooth Finishing Nails

MinWax wood stain in Special Walnut (quart size)

3 Litres of Lepage White Glue (any brand will do.)

Hemlock Door & Window casing moulding- 1 1/2 inch wide

2 Dollar Store 3 inch paint brushes (these were actually purchased at Dollarama.)

Then we came home and started tearing the stairs apart. We already knew the rubber nosings were going to come off easily, and I'd already ripped off all the carpet on the stringers. So next step was to try the lino. This was the moment of truth- but as you already know, it came up easily!

That black stuff is leveling compound the contractor who put the lino in must have used to make sure the stairs were flat. They'd also put down new press board on each tread- which was great- it gave us a flat, level, smooth surface to work on. Perfect. So once one tread was off, we went to town.

That's my Mom ripping lino up. Word of caution: when doing anything that requires force- wear safety glasses!! We almost took a few eyes out. Seriously, they're worth it. Wear em.

After an hour or so the stairs looked like this:

Notice we left every second tread lino'd. That was just for connivence sake- we needed to be able to get up and down. Also notice we'd taken all the trim off. Do this before you pull up your carpet/lino/whatever- it makes a huge mess otherwise.

After that we were tired and called it in for the evening- we were tired!! Today was when the real fun started...

SATURDAY we got going. We head to Home Depot with a list and a mission: get all the supplies for the stairs, and to paint the main area of the house. We succeeded.

But this post is about the stairs.

We went all over Home Depot gathering our loot. And this is what we ended up with. All the supplies (not including tools) cost approximately 195$.

Dry Sheathing for the actual treatment (found in the roofing aisle.)

A big gallon bucket

A caulking gun

PL400 glue in a caulk tube

MinWax Oil-Modified Water Based Poly

Smooth Finishing Nails

MinWax wood stain in Special Walnut (quart size)

3 Litres of Lepage White Glue (any brand will do.)

Hemlock Door & Window casing moulding- 1 1/2 inch wide

2 Dollar Store 3 inch paint brushes (these were actually purchased at Dollarama.)

Then we came home and started tearing the stairs apart. We already knew the rubber nosings were going to come off easily, and I'd already ripped off all the carpet on the stringers. So next step was to try the lino. This was the moment of truth- but as you already know, it came up easily!

That black stuff is leveling compound the contractor who put the lino in must have used to make sure the stairs were flat. They'd also put down new press board on each tread- which was great- it gave us a flat, level, smooth surface to work on. Perfect. So once one tread was off, we went to town.

That's my Mom ripping lino up. Word of caution: when doing anything that requires force- wear safety glasses!! We almost took a few eyes out. Seriously, they're worth it. Wear em.

After an hour or so the stairs looked like this:

Notice we left every second tread lino'd. That was just for connivence sake- we needed to be able to get up and down. Also notice we'd taken all the trim off. Do this before you pull up your carpet/lino/whatever- it makes a huge mess otherwise.

After that we were tired and called it in for the evening- we were tired!! Today was when the real fun started...

7.21.2012

The Lino!

So my Mom arrived on Thursday night and ever since we've been getting ready to start fixing the stairs. Excellent. One of the first hurdles was to determine just how hard getting the lino off the stairs was going to be. The good news is - whoever installed this stuff, either didn't know what they were doing, or used the wrong glue. I'm okay with that. Saves me time!

So Mom and I tried a test strip before our trip to Home Depot- just incase it wouldn't come off easily and we were going to need a scraper. That doesn't appear to be the case! Step two- remove lino- is a go!!

Photographic evidence:

So Mom and I tried a test strip before our trip to Home Depot- just incase it wouldn't come off easily and we were going to need a scraper. That doesn't appear to be the case! Step two- remove lino- is a go!!

Photographic evidence:

Off to Home Depot we go!

Subscribe to:

Posts (Atom)